Our company and our partners store or access information on devices, such as cookies, and process personal data such as unique identifiers and standard information that the device sends for the purposes described below. You can give your consent to the above processing by clicking on the "Accept all" button. Or you can refuse to provide it and change your preferences by clicking the "Manage settings" button. Your preferences will only apply to this website. We do not need your consent for some forms of processing your personal data. You can change your preferences at any time by returning to this page or visiting our privacy policy.

Do you need the material of your choice

to be adjusted?

We are here to help.

We can adjust the sizes and types of surfaces of perforated materials.

We can cut/shear, bend, curl or weld metal sheets as well as expanded metal for you.

And we will take care of all the finishing jobs.

Just choose the design to your liking

PERFO LINEA is a manufacturer that uses 3 different types of machines to fabricate its perforated sheets:

- all-across perforating press perforating the full width of sheet

- presses for sheets of up to 12 mm thickness

- stamping/punching machines to stamp holes, grooves, corners and other shapes of holes

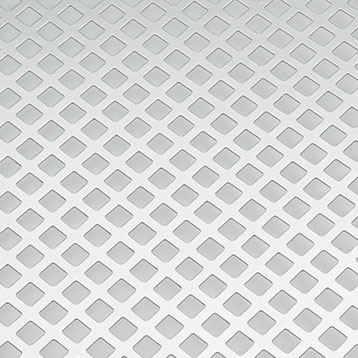

Basic types of perforations:

- Rv round staggered

- Rg round in line (straight)

- Rd round diagonal

- Qg square in line (straight)

- Qv square staggered

- Lv oval staggered

- Lg oval in line (straight)

- Hv hexagonal staggered

- Ss ornamental and special

Countersunk holes are also possible.

The letter P is used in the code.

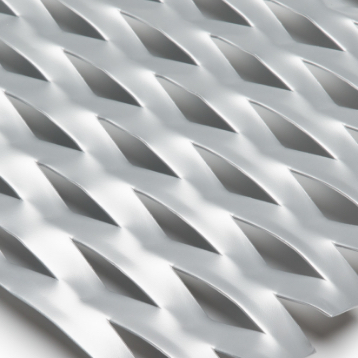

Expanded metal is made from sheet panels or coiled sheets. Then it is straightened, cut and can also be flattened. The letter F is used in the code.

Basic types of mesh patterns:

- TR diamond-shaped

- TQ square

- TE round

- TH hexagonal

- TD ornamental

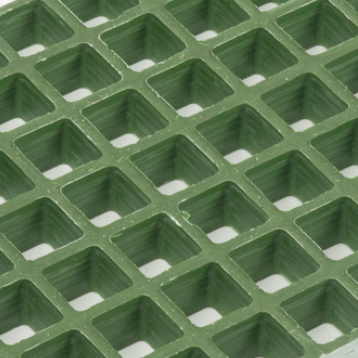

Four types of floor gratings and stair treads are made:

- Pressure-locked gratings

- Welded gratings

- Expanded metal gratings

- Composite gratings

All the above types of gratings are made in a number of mesh patterns. Pressure-locked gratings are the most variable type. Gratings can be furnished with anti-slip surface finish.

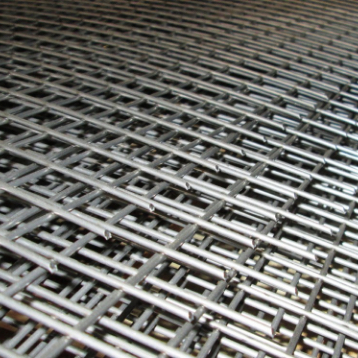

Welded wire mesh screens are made by resistance welding in a variety of mesh sizes and wire diameters.

Crimped and pressure-locked fencing is made by weaving pre-shaped wires.

The mesh pattern is mostly square but oblong mesh can also be made.

The shape in fencing material can be changed diagonally.

It is used in handrails along staircases.

Conveyor belts PERFO LINEA are made of wire. They have a really specialised application and are mostly used where the common rubber, plastic or textile belting cannot be applied.

We will adjust the dimensions for you

We can shear perforated sheets and expanded metal up to the thickness of 10 mm. Maximum cutting length is 3000 mm.

Commonly, we cut materials up to the thickness of 20 mm. Special saws are used to cut expanded metal sheets. This ensures that the mesh is not distorted or deformed on the edges. This is especially welcome when you intend to use the material for architectural purposes. Expanded metal sheets fit well together and, at first glance, the cutting line is not visible.

We will adjust the shape

We will expertly bend, curl or edge the material to the desired shape. .

We can bend perforated sheets to the maximum length of 6 000 mm and thickness of 5 mm. We can bend expanded metal sheets up to the maximum length of 6 000 mm, depending on the type.

We curl perforated sheets and expanded metal to the maximum size of 1 500 x 3 000 mm and material thickness from 1 mm to 6 mm. We perform edging on steel and aluminium perforated materials up to the thickness of 6 mm and length of 6 000 mm. We perform edging on stainless steel sheets up to material thickness of 4 mm and length of 6 000 mm.

We can weld light structures

We can weld steel, aluminium and stainless steel structures up to 1 000 kg. We will take care of high-quality welding on fence panels, floor gratings, pressure-locked stair treads and treads from expanded metal, frames for handrails with panels, balcony handrails, façade panels from perforated sheets and expanded metal, outdoor sun-shading panels and other products within your projects.

We can perforate your metal sections

We will take care of perforating hollow sections from steel, galvanised, aluminium as well as stainless steel material. Perforated material will come in useful for industrial racking systems, when installing electric cable systems, during the construction of industrial premises, when building machines and other equipment. Just select the type of holes and the required pitch. We can adjust perforated sections up to 3000 mm long.

We can master any project

We will manufacture your selected product or adjust it to meet your specific needs. We specialise in fabricating the tools for punching metal sheets, for manufacturing expanded metal and pressure-locked gratings.

- We use hundreds of well-proven tools that can be used without delay.

- We develop our own tools to meet any wishes of the architect or designer.

- New tools are made in our well furnished tool shop.

- We pay great attention to regularly maintaining and sharpening all our tools.

01